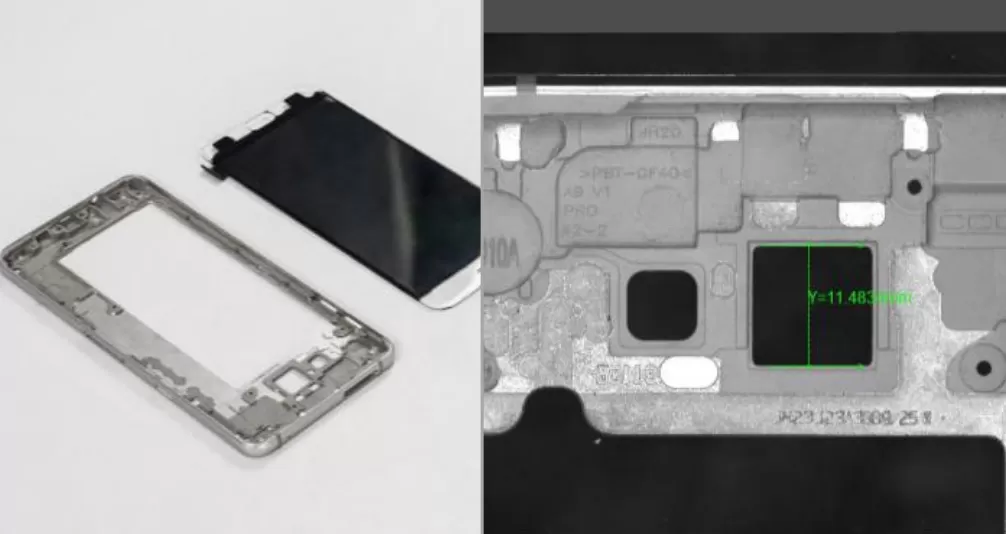

Qualitest provides a wide range of VMM - 2D and 3D Vision Measuring Machine which is widely used in electronic industry, medical devices, LCD, aerospace and other industries measurement.

Vision measuring machines are extensively utilized across industries including machinery, electronics, molds, injection molding, hardware, rubber, precision stamping, connectors, mobile phones, home appliances, printed circuit boards, medical equipment, clocks, tools, military, electricity, bridges, ships, aerospace, and more. They play a crucial role in achieving precision measurements and ultimately ensuring quality control.

|

|

|

|

|

The Vision Measurement Machine, also known as a non-contact measurement instrument, VMM - Vision Measuring Machinetwo-dimensional measurement instrument, and 2.5D measurement instrument, has become an indispensable tool with the advancement of modern industrial high-precision and micro-manufacturing industries. Departing from traditional methods, it employs non-contact optical vision measurement techniques to swiftly and precisely measure geometric dimensions and positional tolerances. This approach has gained widespread acceptance due to its effectiveness in high-precision measurement applications. |

|

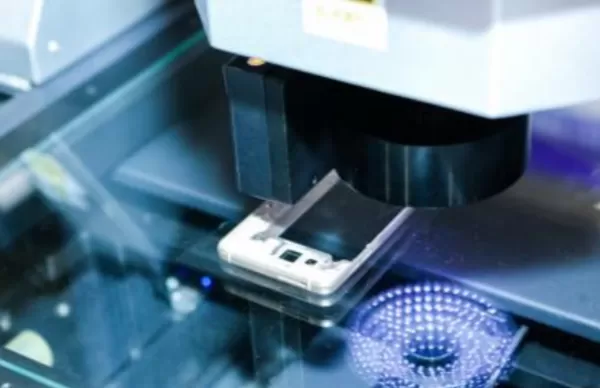

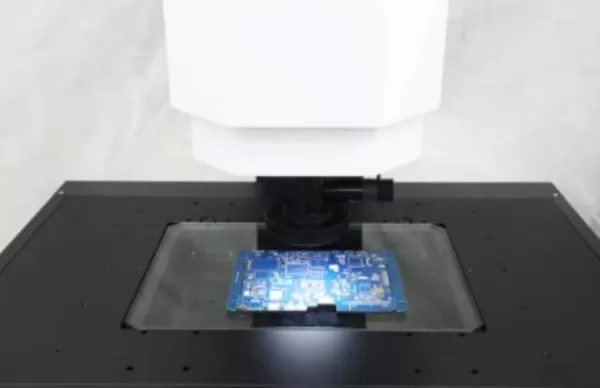

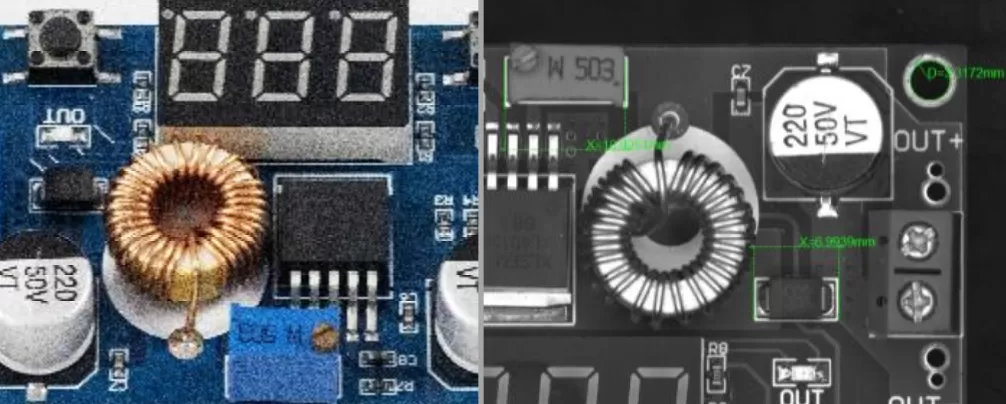

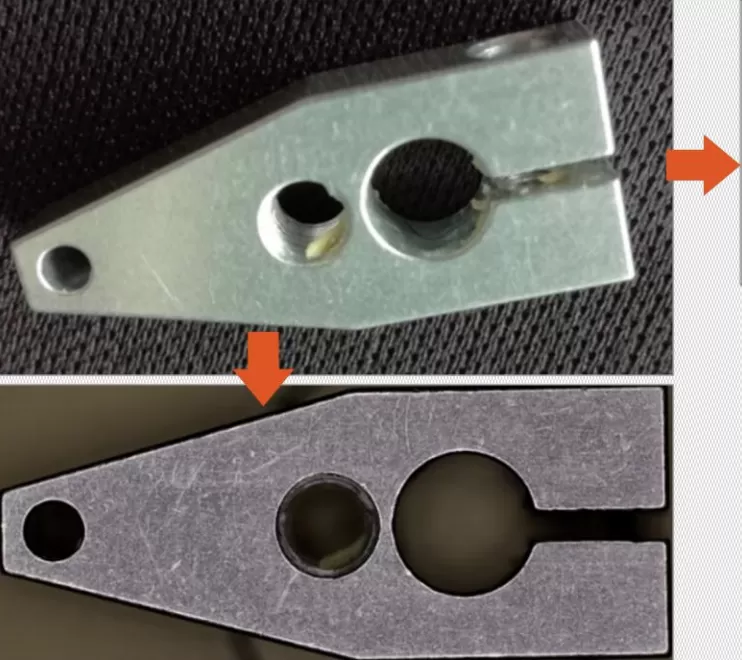

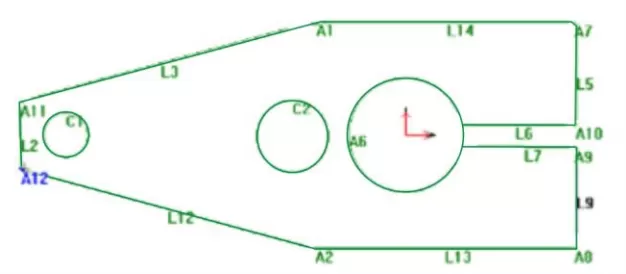

Optical measurement instruments (VMM - Vision Measuring Machine) are well-suited for various fields where coordinate measurement is essential, including mechanical, electronic, instrumentation, hardware, and plastics industries (such as molds, screws, metals, accessories, rubber, PCB boards, springs, hardware, electronics, plastics, aviation, aerospace, etc.). They address the limitations of traditional tools like vernier calipers, micrometers, and projectors, offering a combination of high precision, efficiency, and reliability through the integration of optical, mechanical, electronic, and computer image processing technologies. Utilizing an optical magnification system, the Vision Measurement Machine magnifies the measured object, while a CCD camera system captures image features sent to the computer for analysis. This enables efficient detection of contour and surface shape dimensions, angles, and positions of intricate and precise components, facilitating automatic microscopic inspection and quality control. Measurement data can be imported into software like AUTOCAD to create comprehensive engineering drawings, as well as generate documents in formats such as DXF and IGS. Additionally, data can be input into WORD, EXCEL, and SPC statistical analysis software to produce CPK values and various statistical reports. |

|

|

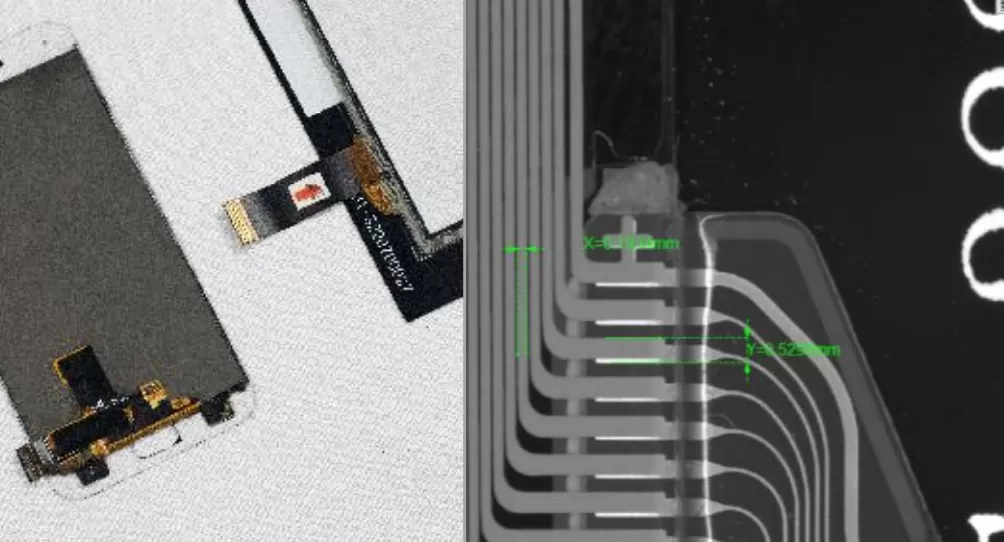

With the rapid evolution of electronic products, the utilization of ribbon cables is experiencing a significant surge. Nearly every electronic device you encounter today incorporates ribbon cables. These cables are characterized by their softness, thinness, and susceptibility to damage. Testing points tend to be concentrated. Zhongwang Precision's independently developed and manufactured optical imaging measuring instrument is tailored for two-dimensional plane dimension detection. It features simple operation and delivers a substantial enhancement in production efficiency. |

|

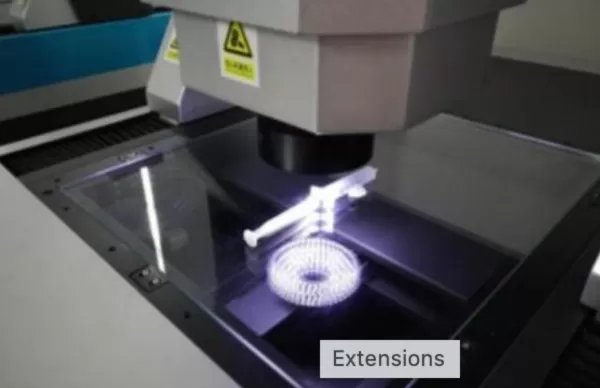

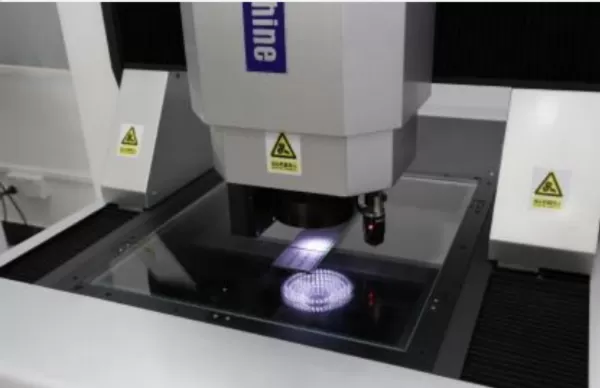

In response to market demands, our company has developed a laser flatness detector designed for various industries, including:

|

|

|

Our laser flatness detector offers precise and reliable flatness measurement across different sectors, contributing to improved product quality and manufacturing efficiency. |

|

The instrument is versatile and suitable for a wide range of applications, including PCBs, nameplates, printing, TouchPanels, glass mesh plates, chips, steel mesh, silk screen mesh plates, and TouchPanel/glass assemblies. Its capabilities include measuring external dimensions, position, line width, flatness, thickness, curvature, and hole size. |

|

|

Particularly for cables, characterized by their soft and easily foldable material and concentrated testing locations, a precision optical vision measuring instrument has been developed and produced, tailored specifically for two-dimensional size detection of cables. Its user-friendly interface and straightforward operation significantly enhance production efficiency in cable manufacturing processes. |

|

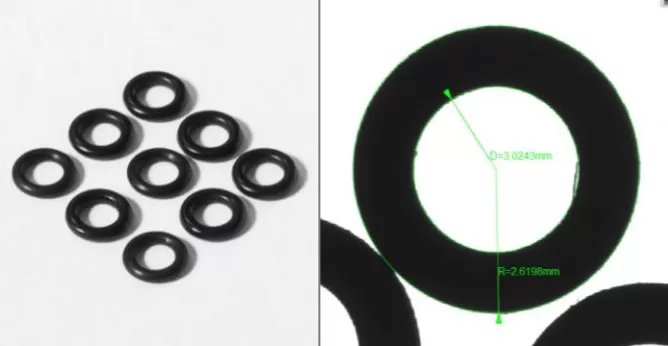

The high-precision Vision Measuring Machine serves a variety of purposes including seal ring dimension detection, seal ring defect detection, rubber product appearance dimension detection, rubber seal edge detection, automotive seal strip contour measurement, plastic product inspection, and more. Its capabilities extend to detecting the inner and outer diameters of seal rings, groove size, missing material, burrs, small pits, perforations, fractures, and other surface defects with exceptional precision. |

|

|

The high-precision imaging instrument excels in achieving measurements such as outer diameter, inner diameter, pitch diameter, pitch, lead, thread profile, and thread angle in thread detection applications. Characterized by its rapid measurement speed and remarkable accuracy, this instrument is particularly advantageous when facing complex measurement requirements. It finds applications across various industries including hardware screws, lead screws, gears, springs, mobile phone accessories, plastics, and others, where precise thread measurements are essential. |

|

The high-precision imaging instrument (VMM - Vision Measuring Machine) finds valuable application in gear detection, where it excels in detecting various parameters including gear addendum circle, dedendum circle, pitch, gear profile deviation, helix deviation, radial runout, shaving cutter profile, and hobbing cutter profile deviation. This instrument (VMM - Vision Measuring Machine) ensures accurate and reliable measurements crucial for quality assurance in gear manufacturing processes. |

|

|

Powerful Data Exchange Function: The measuring instrument (VMM - Vision Measuring Machine) seamlessly converts workpiece measurements into CAD documents in real-time, akin to duplicating the data. Additionally, CAD drawings can be imported into the measurement software for direct comparison, streamlining the inspection process and facilitating efficient data analysis. |

| Powerful Photo Function: Our fully automatic imaging instrument (VMM - Vision Measuring Machine) features a robust mapping and photo function designed to meet stringent quality inspection requirements for appearance. Products undergo aerial photography, ensuring any flaws in appearance are captured with precision and transparency. This visual evidence enhances the credibility of our inspection reports, providing indisputable documentation of product quality. | |

|

Straightness |

Flatness |

Roundness |

Parallelism |

Perpendicularity |

Angularity |

Symmetry |

Cylindricity |

Line Profile |

Concentricity |

Position |

Surface Profile |

Comment