Package Drop Tester Technical Specifications

Type: A B C

Max. Load of Dropping Platform: 60 KG

Moving Speed: 2000 mm/min

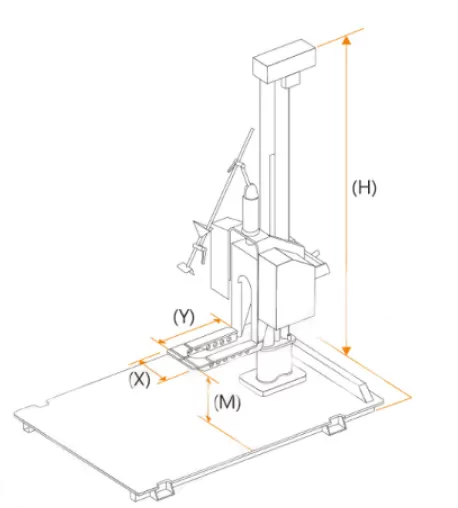

Max. Testing Height (M): A: 130 cm B:180 cm C:200 cm

Min. Testing Height (M): 30 cm

Dropping Platform Area (X‧Y): 27 x 47 cm

Max. Object Size: 80 x80 x height unlimited

Operation Method: Wiring Box Operation

Buffer Device: Hydraulic Buffer Device

Air Pressure: 0.5 MPA

Voltage: Single Phase 220V, 8A (110V available upon request)

Height (H): A: 205 cm B: 266 cm C: 288 cm

Weight (excluding base plate): A: 218cm B:366cm C:375 cm

During drop testing, in addition to the main equipment, it's essential to release the samples onto a flat and rigid surface (base plates). Our instrument offers a selection of commonly used base plates that can be adjusted to fit your sample dimensions. If your samples have unique sizes, we can design custom base plates to meet your specific requirements.

| Base Plate Dimensions (Optional) | |||||

| 85x150 cm | 120x150 cm | 120x180 cm | 150x180 cm | 180x180 cm | 240x150 cm |

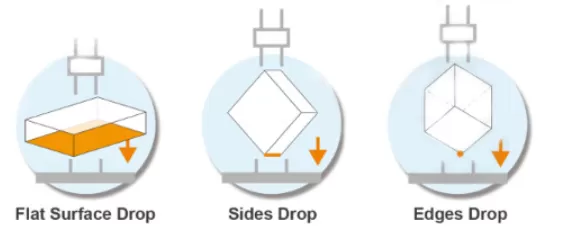

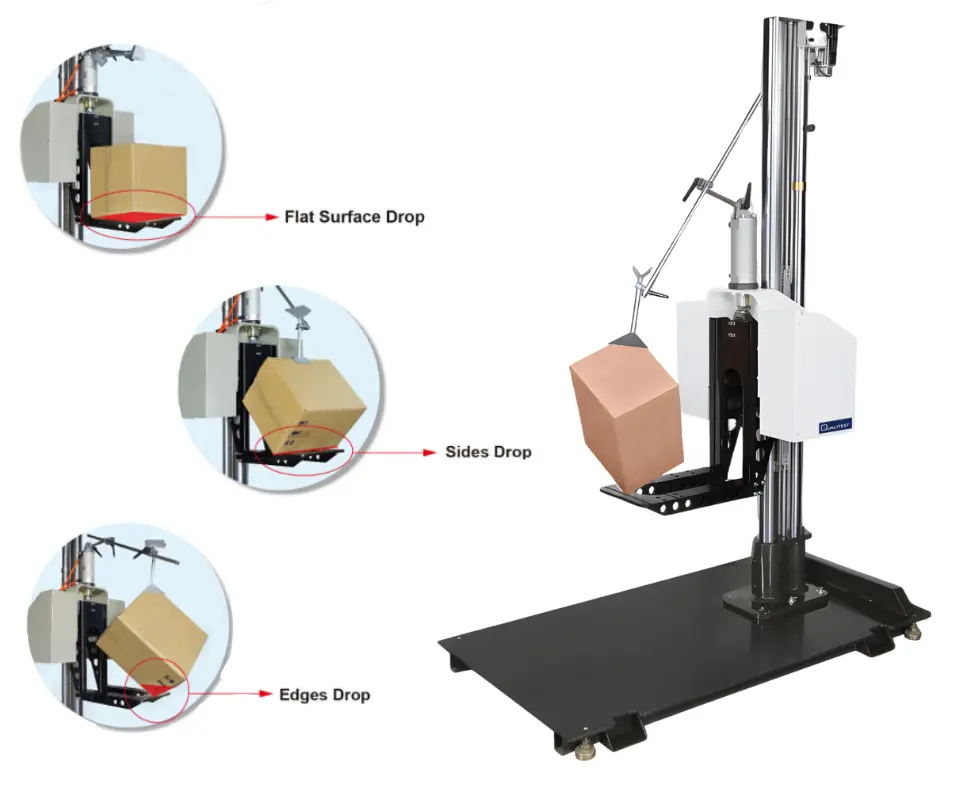

What does the term "one corner, three sides, six faces" signify?

According to standards, this involves conducting a drop test on 10 specific parameters. These parameters include the weakest corner, the three adjacent sides to that corner, and six designated faces. If the packaging or the product inside it sustains damage, deformation, functional irregularities, or any other issues during the test, it is classified as a test failure.

English

English

Comment