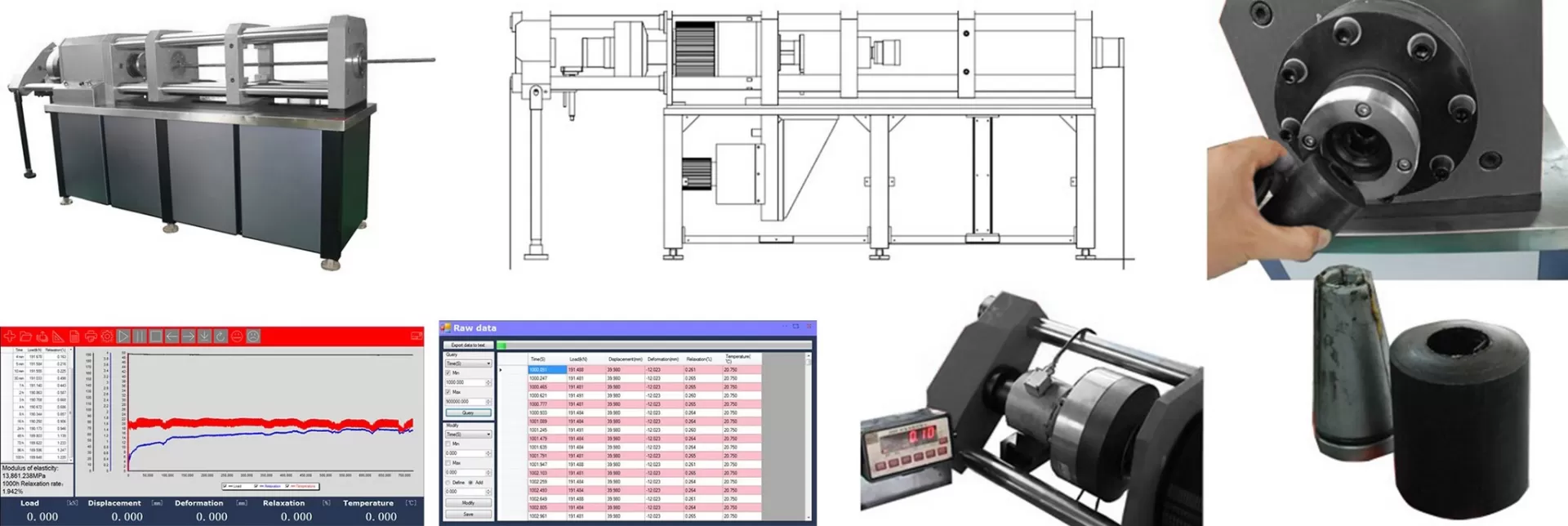

Stress Relaxation Tester for Reinforcing and Prestressing Steel Technical Specifications

| Model | QT-SR-200 | QT-SR-300 | QT-SR-400 | QT-SR-500 |

|---|---|---|---|---|

| Standards | ASTM E328, ISO 15630-3 | |||

| Capacity | 200kN | 300kN | 400kN | 500kN |

| Measuring Range | 8 – 200kN | 12 – 300kN | 16 – 400kN | 20 – 500kN |

| Load Resolution | 7N | 10N | 12N | 15N |

| Load Accuracy | ±1% | |||

| Load Measuring Accuracy | ±0.1% of reading to 1/100 of load weighing system capacity meets or exceeds the requirements of the following standards: ISO 7500-1, EN 10002-2, ASTM E4, JIS B7721 | |||

| Creep of Load Cell | 30 minutes ≤ 0.02% | |||

| Position Accuracy | ±0.5% | |||

| Horizontal Span | 1850mm | |||

| Ball Screw Stroke | 100mm | |||

| Loading Speed | 100 - 5000N/S | |||

| Speed Accuracy | Set speed < 0.05% - Max. Speed: ±1%, set speed ≥0.05% - Max. speed: ±0.5% | |||

| Temperature Accuracy | Temperature sensor resolution: 0.1°C, Temperature sensor accuracy: ±0.3°C | |||

| Position Measurement Accuracy | ±0.01 of reading or 0.0001 mm, whichever is greater | |||

| Specimen Dimensions | ||||

| PC Strand (mm) | Φ12.7 - Φ15.24 | Φ12.7 - Φ15.24 | Φ12.7 - Φ15.24 | Φ15.2 - Φ21.8 |

| PC Wire (mm) | Φ3 - Φ9 | Φ3 - Φ9 | Φ3 - Φ9 | Φ3 - Φ9 |

| PC Bar (mm) | Φ7 - Φ18 | Φ7 - Φ18 | Φ7 - Φ18 | Φ7 - Φ18 |

| Power Supply | Please specify voltage and frequency before placing the order. Standard operational voltages 3ph, 220/380VAC, 50-60 Hz, Power must be free of spikes and surges exceeding 10% of the nominal voltage. | |||

| Operating Temperature | 0 to +38°C (+32 to +100°F) | |||

| Humidity Range | 10% to 90% non-condensing | |||

| Storage Temperature | -40 to +66°C (-40 to +150°F) | |||

| Machine Dimension | 1950 x 540 x 1015mm (L x W x H) | |||

| Weight | 1400kg | |||

| Standard Configurations | ▪ Main unit ▪ Servo systems: driver and motor ▪ Synchronous toothed belt ▪ Anchorage ▪ QualiSoft ▪ Linear gauge extensometer ▪ Control unit ▪ Speed reducer ▪ Temperature recorder ▪ Computer ▪ Printer |

|||

|

||||

| The load cell can be calibrated directly on the testing machine without needing to remove it for external calibration. A master load cell is available, which can be installed alongside the machine’s load cell to perform the calibration process in place. This method ensures efficiency and accuracy, eliminating the need for disassembly and external calibration equipment. | Anchorage | |||

|

|

|||

English

English

Comment